-

JDB solidum-lubricating afferentem JFBB Metrica Autolubricans Sine Oleo Graphite Flange Ferens Bushing

JDB solidum-lubricating afferentem JFBB Metrica Autolubricans Sine Oleo Graphite Flange Ferens Bushing -

JDB solidum-lubricating afferentem JDB-V Steel embedded gerunt repugnant solidum-lubricating afferentem

JDB solidum-lubricating afferentem JDB-V Steel embedded gerunt repugnant solidum-lubricating afferentem -

Oleum-retinentes bimetallic CC # B oleum-retinens bimetallic afferentem (ferro backing + aeris sinter in solidum lubricating dispersit)

Oleum-retinentes bimetallic CC # B oleum-retinens bimetallic afferentem (ferro backing + aeris sinter in solidum lubricating dispersit) -

Oleum-retinentes bimetallic Gerunt, repugnans auto-lubricating oleum-embedded CC # F Fleged

Oleum-retinentes bimetallic Gerunt, repugnans auto-lubricating oleum-embedded CC # F Fleged -

Oleum-retinentes bimetallic CC # P5 auto-lubricating oleum-retinentes gerunt laminam - humilis friction afferentem superficies

Oleum-retinentes bimetallic CC # P5 auto-lubricating oleum-retinentes gerunt laminam - humilis friction afferentem superficies -

SF-I oldless afferentem SF-1P recipere Motion Self-Lubricating Composita Bushing

SF-I oldless afferentem SF-1P recipere Motion Self-Lubricating Composita Bushing -

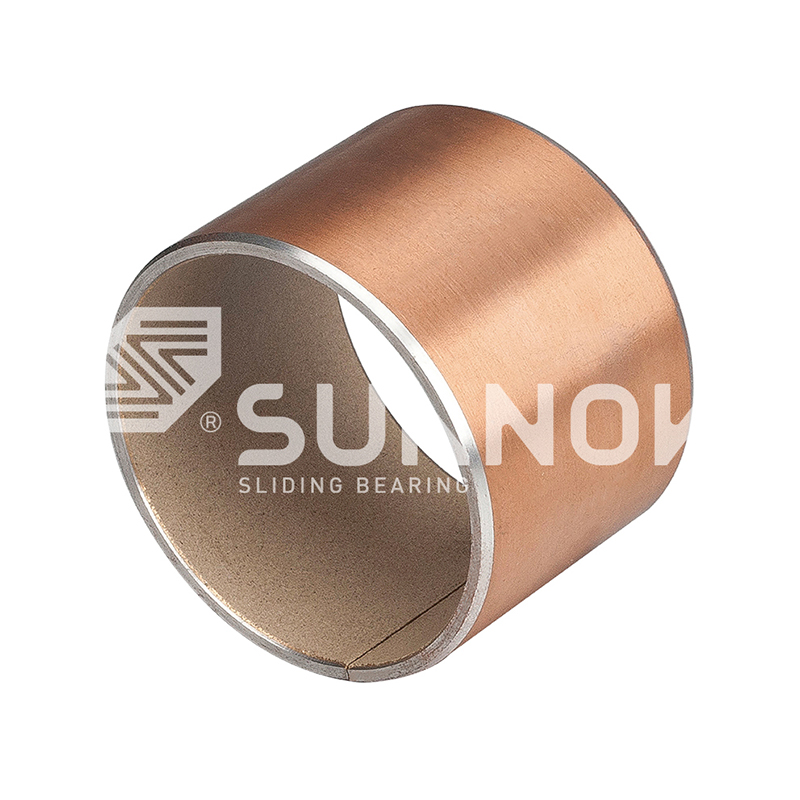

FB090 aere involvit portantes FB091 aeris involvit afferentem

FB090 aere involvit portantes FB091 aeris involvit afferentem -

FB090 aere involvit portantes FB094 aere involvit portantes cum signacula

FB090 aere involvit portantes FB094 aere involvit portantes cum signacula

Solidum-lubricating aere afferentem: A greaseless solutio ad modern industria

News industria-Introduction: solidum-lubricating aere afferentem: A greaseless solutio ad modern industria

Traditional afferentem systems confidunt in constant externum lubricatae, quod saepe est iusto oiling aut greasing. Hoc sustentationem non solum tempus-perussi et labvel-intensive sed etiam ad problems in pulvere, umida, aut contaminari environments. Et leakage vel contaminationem lubricants est a significant provocatione, praesertim ad industries cum stricto munditia requisita sicut cibus processus, medicinae apparatu et textilia.

Solvere problems Solidum-lubricating aere afferentem fuit developed. Hoc est amet afferentem technology quod Achieves sui sufficient operationem sine externa lubricatae ab embedding solidos lubricants (ut graphite, ptfe) aequaliter in raro matricem. Hoc unique consilio permittit ad portantes ad automatically dimittere lubricating components onto ad friction superficiem in operationem, formatam stabile lubricating film quod efficaciter reduces frictio et gerunt.

Comparatio traditional gestus et solidum-lubricating aes gestus

| Pluma | Traditional Slide Gestus (requirit externum lubricatae) | Solidum-lubricating aere afferentems |

| Lubrication modum | Requirit iusto etiam oleum et uncto | Internum solidum lubricant est statim dimisit; nullum externum lubricatae opus |

| Sustentationem frequency | Altum (requirit ordinarius inspectionem et lubricant replenishment) | Minimum (virtute sustentationem-liberum) |

| Contagione periculo | Princeps (Lubricant leakage potest contaminare elit vel products) | Maxime humilis (non oleum leakage, environmentally amica) |

| Convenit environments | Pronus ad defectum in pulvere aut dura ambitus; postulat additional signantes | Operatur stabiliter in pulvere, humidum et dura ambitus |

| Incipiens friction coefficientem | Relative High (Satus) | Relative humilis (solidum lubricant est iam praesentem ad startup) |

| Service vitae | Altus dependens lubricatae sustentationem; potest breviabuntur pauperes lubricatae | Stabilis lubricatae, minimam gerunt, iam officium |

| Summa cost dominii | Maximum costs ad sustentationem, laborem et lubricants | Paulo altius initial investment, sed nimis longo-term sustentacionem costs |

Per hanc collatio, ut patet quod Solidum-lubricating aere afferentem Non solum replacement sed provectus solution quod significantly amplio apparatu reliability, lowers operating costs et enhances environmental salus.

Quid est solidum-lubricating aere portantes?

A Solidum-lubricating aere afferentem Est summus perficientur slide afferentem quod combines robore a metallum vulvam cum oleum-liberum proprietatibus solidum lubricant. Est exactione composita structuram, non iustus simplex coating de Lubricant super superficiem. Haec more isti gestus in basi utor Sinai aut projiciuntur basis, cum solidum lubricants sicut graphite, molybdenum disulfide (Mos2), aut polytetrafluoroethylene (Mos2), aut polytetrafluoroethylene (Ptfe) embedded uniformiter in vel in superficiem.

Core principle operationis ejus, quod est ut afferentem fugit, in calidum generatae friction causas solidum lubricant embeddddddddddddddddddddddddddded in superficiem et constanter et in superficiem. Hi solidum lubricating particulas formare tenuis, durabile transferre film inter afferentem et hastile. Hoc lubricating amet est clavis ad portantes scriptor Oleum-Minus GRATIA capability. Efficaciter separat ad friction superficiebus, significantly reduces ad friction coefficientem, ita obscuratis gerunt et ensuring afferentem currit blete sine externa lubricatae.

Hoc consilium facit idealis Uncto-liberum aere afferentem Quia omnino excludit opus ad lubricating olea et greases.

Comparationis communis solidum-lubricating aere portantes types et eorum characteres

| Genus | Processu | Lubricant Type | Principalis commoda | Typical applications |

| Circumdederunt afori matrix cum embedded plugs | Solidum lubricant plugs (E.G .: Graphite) mittuntur vel premitur in pre-machined foramina | Graphite, Molybdenum disulfide | Maximum onus capacitatem, gerunt resistentia, idoneam gravibus, officium, humilis celeritas conditionibus | Gravis machina, Hydraulical Engineering, constructione Equipment |

| Segregari aere matrix cum gravi oleum | Aeris et stannum pulveres sunt peccata ad altum temperaturis ad partum a raro structuram, tum impegitur oleum | Lubricating oleum (ut initial lubrication) | Perusta structuram potest absorbet magna moles lubricant, idoneam ad medium-celeritate, lux-officio conditionibus | Familia appliances, officium apparatu, automotive components |

| Composita materia (multi-iacuit structuram) | Steel backing cum shaheretera Sphaerica aes pulveris medio iacuit et superficiem layer Ptfe et plumbum mixtisque | PTFE, plumbum | Maxime humilis frictio coefficient, optimum auto-lubricating perficientur, idoneam ad summus celeritas, medium-officium conditionibus | Pumps, valvulae, Automotive Suspensio Systems |

Intelligendo has genera et characteres adjuvat eligendo aptissimum Solidum-lubricating aere afferentem SOLUTIO pro propria applicationem necessitates.

GB71 Nahams Lachge Bushing humerum genus vexillum solidum-lubricating afferentem

Applications et commoda solidum-lubricating aes gestus

Ad unicum perficientur de Solidum-lubricating aere afferentem Facit illud idealis choice pro amplis exigens environments requirere princeps reliability, humilis sustentacionem et non contaminationem. Non solum autem afferentem sed versatile Auto-lubricating bushing et Oleum slide laminam , Late in variis illapsum et gyratorius motus applications.

Core Application areas

- Construction et gravibus machinery: In articulis excavators, grues et bulldozers, traditum lubrants facile contaminari luto pulverem et aqua ducens augeatur. Solidum-lubricating aere afferentems Potest operari stabiliter in his dura environments, reducing sustentationem et downtime.

- Hydraulicarius et Marine Engineering: De ampla aquae soliflai, Sluice portas et underwater apparatu, in contactu aqua et humidum ambitus diu. In Oleum-Minus GRATIA Pluma prohibet lubricant contaminationem aqua, cum eorum corrosio resistentia est etiam plene assuetudo.

- Cibum et medicinae apparatu: Hae industries maxime excelsum munditiam requisita, ubi quis lubricant leakage potest contaminare products. Uncto-liberum aere afferentems Ensure apparatu potest operari secure sine oleum, occurrens stricte hygiene signa.

- Automation et robotics Industrial: In automated productio lineas requirere precise, contaminationem libero motus, Compositum gestus Providere firmum frictio perficientur, cursus lenis motus robot arma et TRADUCTOR zona.

Principalis commoda

| Genus | Descriptio specifica | Valorem lucrata |

| Reducta sustentacionem | Inhaerens solidum lubricant facit eam Sustentacionem-Free or Sustentatio SOLUTIO, eliminating opus iusto oiling aut greating. | Inferior totalis sumptus dominium (TCO) . Reduces labore costs, lubricant consummatio, et apparatu downtime. |

| RELIQUUM | Traditional Lubrication systems sunt prone ad defectum in dura conditionibus (E.G., altum temperaturis, humilis temperaturis, pulvis, humiditas). Ad perficientur de Solidum-lubricating aere afferentem Est firmum et a elit, efficaciter reducendo defectum elit. | Extendat apparatu lifespan et ensures continuitatem et stabilitatem productio linea. |

| Environmentally amica | In oleum et SCRIPTOR Design omnino excludit periculo lubricant leakage, quod posset contaminare elit et products, praesertim in industries ut hydraulicis, cibum et textile. | Enhances environmental obsequio Creeto a lautus, tutius opus elit pro comitatu. |

| Maximum onus capacity | In bronze matrix provides excellent mechanical strength, allowing it to withstand high loads and impact forces. At the same time, the use of solid lubricants ensures low friction and long life under heavy loads. | Occurrit postulans ipsum requisita , Formans optime in gravibus machinery applications. |

In summary, utilitas Solidum-lubricating aere afferentem is that through technological innovation, it transforms the maintenance burden et environmental risks of traditional lubricated bearings into its core competitiveness, providing modern industry with efficient, reliable, and environmentally friendly sliding solutions.

Quam eligere ius solidum-lubricating aere afferentem

Eligens ius Solidum-lubricating aere afferentem est crucial ad ensuring eius meliorem perficientur per applicationem. Hoc requirit a comprehensive consideratione multiplex technica parametri et operating conditionibus ad aequare afferentem scriptor proprietates cum propria necessitatibus.

Key factores ad considerans

- Onus genus et magnitudine:

- Static onus: In force the bearing withstands when the equipment is stationary.

- Dynamic onus: In force the bearing withstands during equipment operation.

- Impact load: Brevis autem potens instantanei.

Electio basis: Solidum-lubricating aere afferentems Circa vulvam vulgo superioris viribus et duritiosa possint impediendas maiorem et dynamic onerat, faciens apta gravibus machinatione et constructione apparatu. Nam leviori onerat, alia genera compositum Auto-lubricating bushings esset plus sumptus efficax.

- Operating celeritas et PV valorem:

- Operating celeritate (V): In linear speed of the bearing surface.

- PV valorem (pressura X velocitas): In product of load (P) and speed (V), an important indicator of the bearing's working stress. A high PV value means the bearing needs to handle more heat and friction, requiring better lubrication performance.

Electio basis: Diversis solidum Lubricant et matrix junctiones potest aptet ad diversas P. valorem iugis. Exempli gratia, Ptfe-fundatur compositum Solidum-lubricating aere afferentems Sunt plerumque idoneam ad excelsum PV valores et summus celeritas conditionibus, dum graphite, embedded gestus sunt magis idonea ad medium-ad-humilis celeritate, gravibus, officium conditiones.

- Temperatus et environment:

- Temperature: In ambient temperature and the heat generated by the bearing itself. High temperatures can affect the performance of some solid lubricants, leading to failure.

- Environment: In presence of dust, moisture, corrosive chemicals, etc.

Electio basis: In summus temperatus environments, eligere Solidum-lubricating aere afferentem Cum calor repugnans graphite vel specialis mixta matrix. In umida aut pulvere ferendum, eius oleum et SCRIPTOR Properties det illud naturalem commodum, sed necesse est ut solidum lubricant non reflecti chemica cum substantiis in environment.

Ferre lectio parametri collatio mensa

| Pluma | Graphite-embedded solidum-lubricating aere afferentem | PTFE compositum solidum-lubricating aere afferentem | Molybdenum disulfide, embedded solidum-lubricating aere afferentem |

| Basi materia | Cast sive segregare aes | Sextered Rara aes | Cast sive segregare aes |

| LUBRICUS | Graphite | PolytemTrafluoroethylene (Ptfe) et additives | Molybdenum disulfide ($ MOS_2 $) |

| Load capacity | High (Idoneam ad gravibus, officium, humilis-celeritate) | Medium (Apta idoneam ad medium onerat, summus celeritate) | Medium (Apta idoneam ad medium onerat, summus celeritate) |

| Friction coefficientem | Medium ad humilis | Humilis | Humilis |

| Temperature range | Lata, potest sustinere altum temperaturis | Narrower, limited by Ptfe scriptor temperatus resistentia | Lata, idoneam ad altum temperaturis et vacuo environments |

| Typical applications | Construction Machinery, Hydraulical Engineering, Gravis Industry | Automotive components, officium apparatu, textile machinery | Aerospace, vacuo apparatu, praecisione instrumenta |

Per comparatione haec clavis parametri, fabrum et gravida potest verius eligere aptissimum Solidum-lubricating aere afferentem Nam specifica applications, ensuring longa-durat reliability dum Achieving Sustentacionem-Free et oleum Operatio.

Conclusio

In Solidum-lubricating aere afferentem Repraesentat a major progressionis in modern labi afferentem technology. Non est iustus simplex replacement sed summus efficientiam, reliable et environmentally amica illapsum solutio provisum est a unique compositum materia et sui sufficienti lubricatae mechanism.

Fundamentaliter, in core valorem huius ferre mendacium in oleum et SCRIPTOR characteres. Omnino mutat fiduciam traditional gestus in externa lubrication systems, simplifying complexionem sustentacionem officia ut paene non interventus. Hoc non solum significantly reduces operating costs et labor initus sed etiam valde enhances apparatu reliability in pulvere, umida, aut extrema environments.

Comparatio altiore valorem: Traditional Cervis vs. solidum-lubricating aes gestus

| PRAESENTIA | Traditional Lubricated Gestus | Solidum-lubricating aere afferentems |

| Oeconomica beneficia | Requirit Long-term investment in lubricant costs et sustentacionem feodis | Initial investment potest esse leviter altius, sed diu terminus sustentacionem costs sunt valde humilis, ducens ad meliorem summa sumptus dominium |

| Operational efficientiam | Pronus ad auctus friction et reducitur efficientiam ex improprium lubricatae | Friction coefficientem efficaciter lenis et efficiens apparatu operandi |

| Environmental ictum | Periculum of Lubricant Leakage, quod potest contaminare environment et products | Non oleum lacus, omnino environmentally amica, idoneam ad industries cum excelsum munditiam requisita |

| Reliability | Reliability reducitur ausculto externa ambitum (pulvis aqua) | Potest operari stabiliter in dura conditionibus, cum significantly melius reliability |

| Design flexibilitate | Requirit spatium et rivos reservari in lubrication system | Pacto structuram simplifies mechanica consilio et salvet spatium |

Conclusio cum suis praeclara perficientur humilis sustentacionem eget et environmental amicitia Solidum-lubricating aere afferentem Est magis conveniens component in modern industriae consilio. Hoc praebet solidum fundamentum pro automation, sustineri progressionem et summus reliability applications et est momenti coegi pro continua innovation in futurum industrialis sector.

Frequenter Interrogata Quaestiones (FAQ)

I. Quid sunt principalis commoda solidum-lubricating aes gestus?

In main advantages of Solidum-lubricating aere afferentems sunt oleum, maintenance-free, high reliability, and environmentally friendly characteres. Comparari traditional gestus quod requirere iusto lubricatae, quod significantly redigendum sustentationem costs et downtime et praestare exceptionali bene in pulvere, umida, aut contagione-prone ambitus. Simul, eorum robust robustus et vulvam et internum solidum lubrants ensure firmum operationem sub gravibus onerat et complexu conditionibus.

II. Quid clavis factores debet considerari cum eligens solidum-lubricating aere portantes?

Cum eligens ius Solidum-lubricating aere afferentem , Vos postulo considerare compositum ex his key factors:

- Onus genus et magnitudine: Determinare static, dynamic, aut impulsum onerat portantes portabit.

- Operating velocitate: In linear speed of the bearing surface affects friction and heat generation.

- Opus environment: Considerans factors ut temperatus, humiditas, pulvis et chemical corrosio.

- Material iunctura: Ex specifica application, eligere oportet quodam stannum et solidum Lubricant type (E.G., Graphite Ptfe) ad consequi meliorem perficientur.

III. Quid est unicum de Zhejiang Shuangnuo afferentem technology Co., Ltd. scriptor productionem Solidum-lubricating aere afferentems ?

Z Hejiang Shuangnuo afferentem Technology Co., Ltd. Est a manufacturer specialiter in productionem variis auto-lubricating aeris mixturae products usura centrifuga casting, continua casting, metallum fingunt casting, et alia processibus. Et principalis products includit aes, aluminium aes, stannum aes, et alia productae produci secundum National Standard grades. De hoc ex, processibus et producit variis solidum inlaid auto-lubricating afferentem products. In eodem tempore, utitur utitur Technology ad producendum bimetallic products et multis aliis generibus products. Quia ejus instauratio fere X annos, in comitatu est focused in investigationis progressionem, et productionem variis novum auto-lubricating gestus.

In processus of productionem productionem, nostrae comitatu semper inest in independens mittentem productionem rudis materiae ad curare qualitas products ex fonte; Per mittens processus, totum est monitored, et complevit uber probatur a spectrometer ter prius, in et post fornacem ad confirmandas materiam compositionem productum. In National Testing Agency est regulariter commissione temptare materiam compositionem et mechanica proprietatibus productum, et auctoritate test tradit potest providit ut customers in necessitate; In comitatu implementment integrated productio ex materia ad complevit productum processus et plus quam LXXX sets of Advanced CNC Machina Tools, CNC letes, machining centers, et major apparatu. Et fortis productio facultatem efficitur quod materia productio ordinatur ad teloneariorum ad primum tempus, breviores productio cycle.